|

| |

|

|

|

Truss work Part on Plane Truss work Part on Plane |

Conjunction Part on Plane Conjunction Part on Plane |

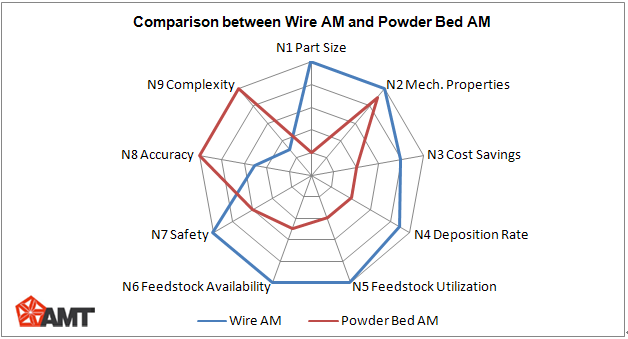

1. Wire AM vs. Powder Bed AM |

Wire AM is a very promising technology for producing large components with moderate complexity, such as stiffened beam. Its strengths and weaknesses comparing with powder bed AM are shown as follows: |

|

N1: Powder BED AM technology can only produce parts of very limited sizes. AMT Metal parts manufactured by Wire AM can reach the size of 6-10 meters long, this enables us to cooperate with industries like aircraft, aerospace, oil and gas etc. |

|

|

N2: The mechanical properties by Wire AM are better than those by powder bed AM due to its 100% dense structure. Besides, with our top perofrmance wires, we AMT, long-term member of the International Titanium Association, guarantee that our parts will be first-class substitutes for those by cast and wrought.

N3: Powder feedstock is much more expensive than wire feedstock across the board.

N4, N5: Wire AM has a much higher material feedstock utilizaition rate up to 100 % and deposition rate 2-4 times than powder bed AM.

N6: Wire AM will provide the users with a wider range and greater availability of feedstock, more various types of Titanium or Nickel alloys etc.

N8, N9: Powder bed AM has a much higher accuracy and complexity than wire AM. |

Our medium complex large metal parts by wire additive manufacturing are ideal for, but not limited to

following Industries:

1. Aircraft frames, structures, and parts

2. Aerospace

3. Oil & Gas Equipment

4 .Industrial Pump Components

5. Nuclear Power Components

6. Industrial Mould |

|

|

|

|

|

|