|

|

|

Unique Nano Stainless Steel Atomized Powders

for Thermal Spraying |

The coating of our Nano Stainless Steel Atomized Powder is of Nano scale and amorphous microstructure. After HVOF metal spraying, the feature of coating is charactered by superior wear resistance, excellent corrosion resistance and good metallurgical bonding. |

Fe |

Cr |

Ni |

Si |

B |

Ti |

C |

Mn |

Mo + Cu + Co |

W + V |

La + Ce + Yt |

Balance |

15-45% |

0-15% |

0.04-5.5% |

2-12% |

0.01-8% |

0.5-8% |

0.01-5% |

0-15% |

0-15% |

0-5% |

|

Properties |

Full Density |

Cost |

Size, um |

Application |

Heat Input |

Wear Resistance |

Corrosion Resistance |

Replacing |

Nano1 |

7.0-9.0 |

Very Economic |

15-45, 38-125 |

HVOF, Plasma, Flame |

AAA |

AA+ |

A+ |

Cr3C2-NiCr, NiBSi, NiCrBSi |

Cr3C2-NiCr |

6.5-6.8 |

Expensive |

15-45 |

HVOF, Plasma |

AAA |

AA |

AAA |

|

Nano3 |

7.0-9.0 |

Very Economic |

15-45 |

HVOF, Plasma |

AAA |

AAA |

A+ |

WC-10Co-4Cr or WC-12Co in economical Applications |

WC-10Co-4Cr or WC-12Co |

14-14.6 |

Very Expensive |

15-45 |

HVOF, Plasma |

AAA |

AAAA |

AA |

|

|

| 2、Unique Nano Stainless Steel Atomized Powders for Thermal Spraying |

| Low Cost High Cost-effective |

Our Nano3 can replace tungsten carbide WC-10Co-4Cr powder or WC-12Co powder for HVOF metal spraying when wear is not so cruelty, while the Cost-effective of Nano3 is about twice than WC-10Co-4Cr powder or WC-12Co powder and also saving the tungsten resource. |

|

|

|

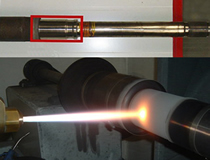

| HVOF Spraying of Oil Drill Rod |

HVOF Spraying of Corrugating Roll |

HVOF Spraying of Electricity Rotor |

|

|

|

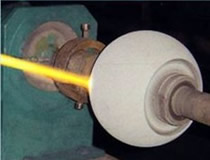

| HVOF Spraying of Valve Ball |

HVOF Spraying of Valve Plate |

HVOF Spraying of Valve Seat and Pole |

Our Nano1 powder can replace Cr3C2-NiCr powder, NiBSi or NiCrBSi powder for metal Thermal spraying, while the Cost-effective of Nano1 is about twice than Cr3C2-NiCr powder. |

|

|

|

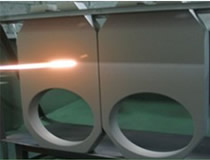

| Drying Cylinder in Paper Industry |

Spiral Powder Feeder / Extruder |

HVOF Spraying and Machining Plunger |

|

|

|

| HVOF Spraying of Draught Fan Rotor |

Spraying and Machining Of MachineryGuide Rail |

HVOF Spraying of Mud Pump |

Standard packaging is by pail with polyethylene liner per 50 kg or by plastic bottle per 4.5 kg.

s

|

|

|

|

|

|